In the 18th century the Potomac River was unnavigable upriver from Georgetown because Little Falls and Great Falls blocked the way. In 1785 George Washington formed the Potomac Company to solve this problem. The company sent crews up and down the Potomac and its tributaries using black powder to blast any impediments to navigation. By 1802 locks had been built around Little Falls and Great Falls opening up the mighty river, at least when the water level was sufficient.

These locks at Great Falls were constructed of Seneca Sandstone extracted from a quarry about 10 miles upriver along the Maryland side of the Potomac. With the completion of these locks, Seneca sandstone soon was available for construction in Washington DC. Its characteristically red color proved very popular and some of the most iconic buildings in the capital city are constructed of this stone, for example, the Smithsonian Castle pictured below.

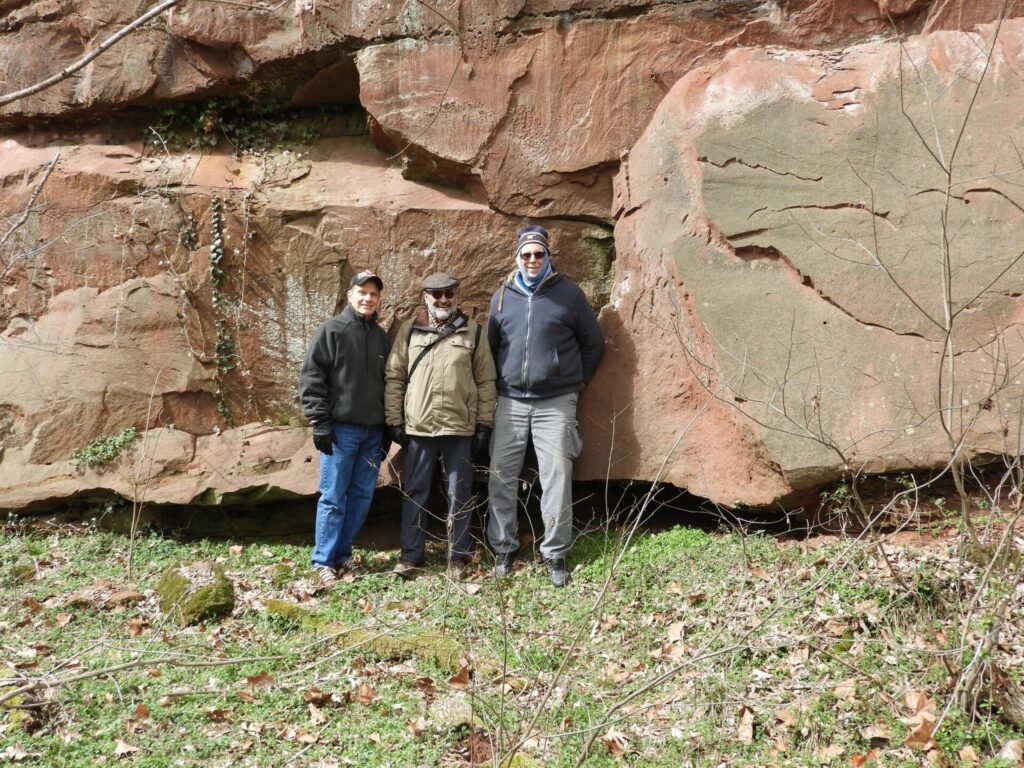

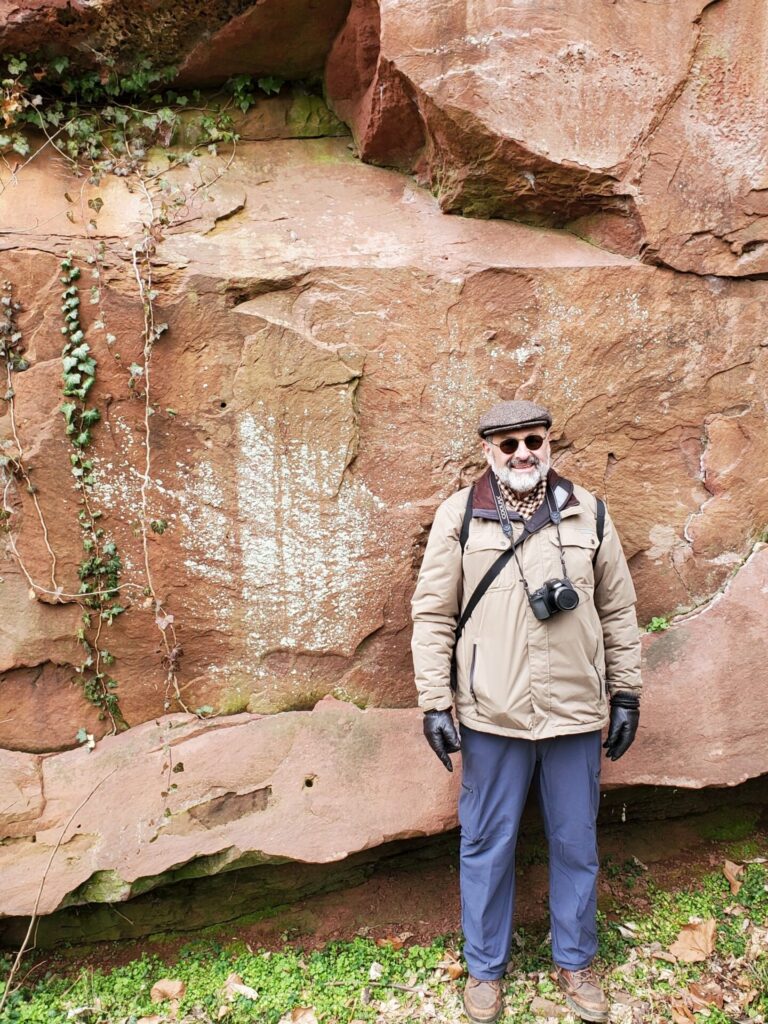

To visit the Seneca Quarry set your GPS to Riley’s Lock on the C&O Canal. Don’t miss the ruins of the 1830’s stone cutting building, a water-powered mill which used reciprocating saws to cut the stone. Although currently in a sorry state, it is hoped that it will soon be rehabilitated.

Above the quarry, although not open to the public is a private residence which was the house provided to the quarry foreman. Most interesting is that the house seemed to serve as a “Style Book” for the quarry, demonstrating various stone sizes and faces which were available.

For more on the Seneca Quarry: “The Smithsonian Castle and the Seneca Quarry” by Garrett Peck

For more on The Potomac Company: “The Potomac Canal” by Robert J. Kapsch

For more on George Washington’s Potomac River vision: “The Grand Idea” by Joel Achenbach

Don’t forget, my book, “Potomac Marble: The History of the Search for the Ideal Stone” is now available. Benjamin Latrobe’s Potomac Marble Quarry is just a few miles upstream from the Seneca Sandstone quarry.

Leave a Reply